UninziIsixhobo seThermoformingiya kuba nenkqubo yokupholisa ezimeleyo, yintoni indima edlalwa koku kwinkqubo yokuqulunqa?

Iimveliso ze-Thermoforming kufuneka zipholile kwaye zibunjwe phambi kokwenza, kwaye ukusebenza kakuhle kokupholisa kusetwa ngokwemveliso ekwiqondo lobushushu lokungunda, elinokuphucula ngcono ukusebenza kakuhle kwemveliso kunye nokuqinisekisa umgangatho wemveliso.

Ukuba ukupholisa akwanele, i-deformation kunye nokugoba kuya kwenzeka lula; ukuba ukupholisa kugqithise, ukusebenza kakuhle kuya kuba kuphantsi, ngakumbi kwiipuntshi ezinamathambeka amancinci, anokubangela ubunzima ekubunjweni.

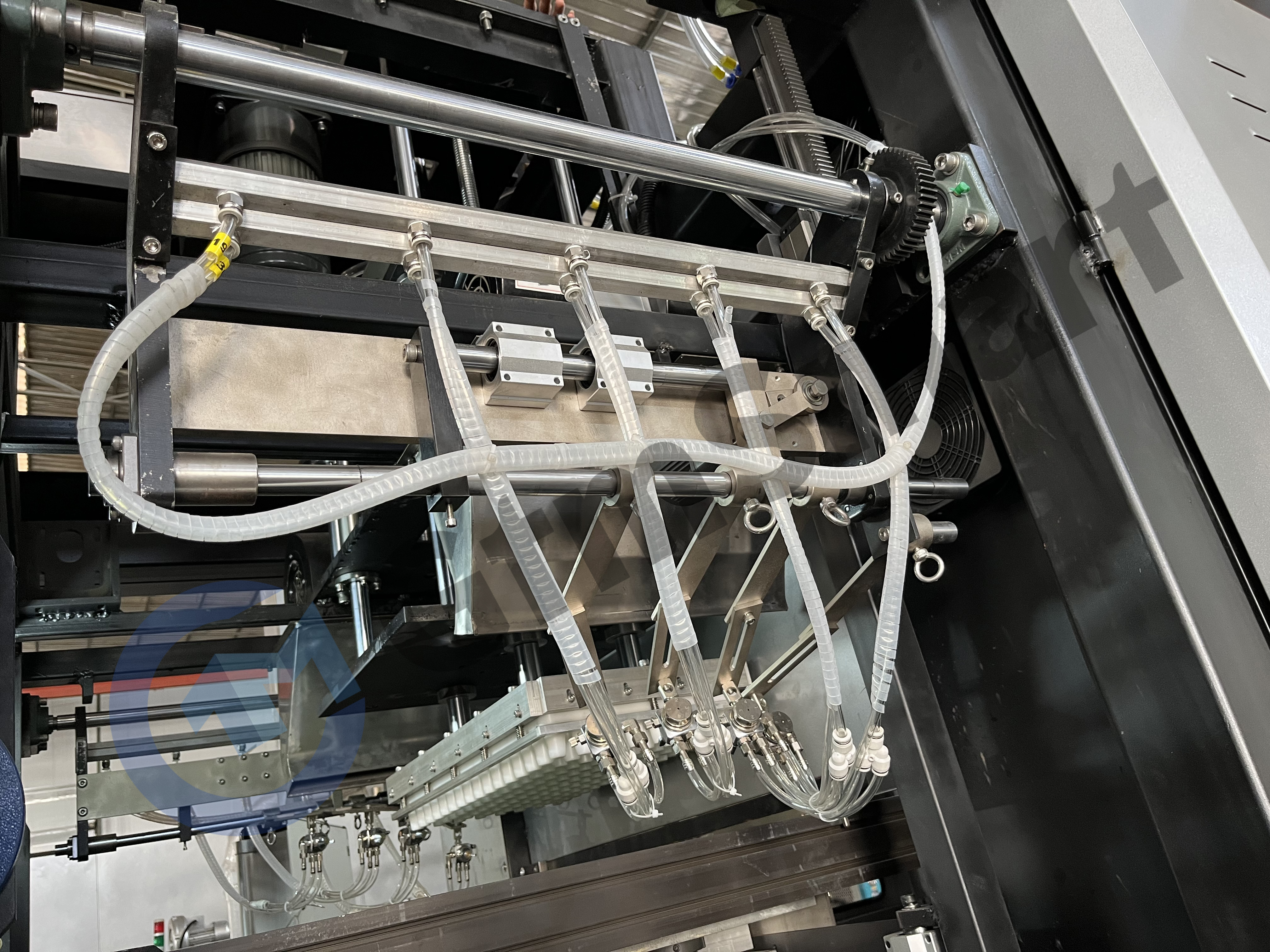

Kukho iindlela ezimbini zokupholisa. Ukupholisa kwangaphakathi kukupholisa imveliso yokuqala ngokupholisa isikhunta. Ukupholisa kwangaphandle kukusebenzisa ukupholisa umoya (ukusebenzisa iifeni okanye iifeni zombane) okanye umoya, inkungu yamanzi, njl. njl. ukupholisa iimveliso. Ukupholisa ukutshiza kwamanzi okwahlukileyo kunqabile ukusetyenziswa, kuba kulula ukubangela iziphene kwiimveliso, kwaye kwangaxeshanye, kunokubangela ukukhutshwa kwamanzi okungahambi kakuhle. Ngokufanelekileyo, zombini iindawo zangaphakathi kunye nezangaphandle ze-workpiece edibene ne-mold zipholile. Njengoko i-PVC kunye nezinye izinto kufuneka zidilizwe kubushushu obuphantsi ngokwentelekiso emva kokubunjwa, kungcono ukusebenzisa isikhunta esinekhoyili yokupholisa ngaphakathi kunye nenkqubo yokupholisa ngokupholisa komoya kunye nokunye ukupholisa ngenkani ukugqiba ukupholisa kweemveliso. Kwiimveliso ezifana ne-polystyrene kunye ne-ABS enokuthi ifakwe kwiqondo lokushisa eliphezulu, i-coil yokupholisa ayikwazi ukufakwa kwi-mold, kwaye iimveliso ezincinci zinokupholiswa ngokwemvelo.

Ixesha lokuposa: Aug-24-2022