Isikhokelo soKhetho kunye nokuSetyenziswa koMbumba weThermoforming Machine

I. Intshayelelo

Itekhnoloji ye-Thermoforming ifumana ukukhula ngamandla kwishishini lanamhlanje lokulungisa iplastiki, kunye nokukhetha kunye nokusetyenziswa komngundo kuba yeyona nto ibalulekileyo ekumiseleni impumelelo yemveliso. Eli nqaku lijonge kwimiba engathandekiyo yokukhetha umatshini wokubumba we-thermoforming kunye nokusetyenziswa, ikubonelela ngesikhokelo esibanzi. Ukusuka kwi-mold yentsimbi echaseneyo kunye ne-polymer molds ukuya ekukhetheni ukhetho phakathi kwe-single-cavity kunye ne-multi-cavity molds, sityhila ingcamango emva kwesigqibo ngasinye.

II. Isishwankathelo seTekhnoloji yeThermoforming

Kwindawo yokwenziwa kweplastiki, ukungunda kuvela njengenxalenye ebalulekileyo, echaza iicontours ezichanekileyo kunye nemilinganiselo yemveliso yokugqibela. Ukungunda kudlala indima ezimbini: ukuququzelela inkqubo yokubumba kunye nokuqinisekisa ukufana kwizinto eziveliswayo. Nokuba zenziwe ngesinyithi okanye iipolymers, ezi zibumba zinegalelo elikhulu kumgangatho kunye nokungaguquguquki kweemveliso ze-thermoformed. Eli candelwana liphonononga ukubaluleka kobumba ekubunjweni kweplastiki, ngokuthelekisa iingenelo kunye nokusetyenziswa kwesinyithi kunye ne-polymer molds. Ngaphezu koko, ihlolisisa iingqwalasela ezibandakanyekayo ekukhetheni phakathi kwe-cavity enye kunye ne-multi-cavity molds, icacisa impembelelo yabo ekusebenzeni kakuhle kwemveliso kunye neendleko ezifanelekileyo.

Imbonakalo-mhlaba ye-thermoforming iyaguquka rhoqo, iphenjelelwa yinkqubela phambili yetekhnoloji kunye neemfuno zentengiso. Kweli candelo, sihlalutya iintsingiselo ezikhoyo ezibumba ishishini le-thermoforming kunye neemfuno ezihambelanayo abazibekayo. Ukusuka ekudityanisweni kobuchwepheshe bedijithali ukuya kugxininiso olwandayo kwizenzo ezilungele indalo, ukuqonda ezi ndlela ziqhelekileyo kubalulekile ukuze uhlale unolwazi ngophuhliso lweshishini. Ukuqonda imeko yangoku kunye noqikelelo lwexesha elizayo lubonelela ngembono ebanzi yecandelo le-thermoforming, ukunceda iingcali ekulungelelaniseni imisebenzi yazo kunye neemfuno ezivelayo.

III. Iindidi zokuMbumba koomatshini beThermoforming

A. Ukungunda kwesinyithi vs. Iipolymer Molds:

Uhlalutyo lokuthelekisa izinto eziluncedo kunye nezingeloncedo

Ukubumba kwesinyithi kunye nokubumba kwe-polymer kubonisa ukhetho olubini olwahlukileyo kwi-thermoforming, nganye inesethi yayo yeenzuzo kunye neengxaki. Imibumbo yesinyithi, eyilwe nge-aluminiyam okanye intsimbi, iqhayisa ngokuhlala ixesha elide kunye nokuchaneka, iqinisekisa ukusetyenziswa ixesha elide kunye nemveliso ekumgangatho ophezulu. Kwicala le-flip, iindleko zabo zemveliso kunye nobunzima bunokuba yimiba ethintelayo. Ngokwahlukileyo koko, ukubumba kwepolymer, okuhlala kusenziwa ngezinto ezifana ne-epoxy okanye iiresin ezihlanganisiweyo, zibonelela ngeendleko-zokusebenza kunye nobunzima obulula. Nangona kunjalo, banokubonisa ixesha elide kunye nokuchaneka okuncinci xa kuthelekiswa nabalingane babo besinyithi. Eli candelwana lihlola ngokucokisekileyo i-pros and cons ehambelana nentsimbi kunye ne-polymer molds, ukunceda abavelisi ekwenzeni izigqibo ezisekelwe kwiimfuno zabo ezithile.

Izicelo ezifanelekileyo kwiiMathiriyeli ezahlukeneyo

Ukufaneleka kwesinyithi okanye i-polymer molds kuxhomekeke kwisicelo esithile ngaphakathi kwenkqubo ye-thermoforming. Imibumbo yesinyithi ikhanya kwiimeko ezifuna iinkcukacha ezintsonkothileyo, ukunyamezelana okuqinileyo, kunye nokuqhuba imveliso eyandisiweyo. Ngokwahlukileyo, ii-polymer molds zifumana i-niche yazo kwiiprojekthi ezinomthamo ophantsi wemveliso, okuvumela ukulingana phakathi kweendleko ezifanelekileyo kunye nomgangatho owamkelekileyo. Ngokuphonononga iimpawu ezahlukileyo kunye nokusetyenziswa okufanelekileyo kwezi zixhobo zokubumba, eli candelo likhokela abavelisi kukhetho olulungileyo oluhambelana neenjongo zabo zokuvelisa.

B. IiMngundo ze-Single-Cavity ngokumelene ne-Multi-Cavity Molds

Iingqwalasela zokuSebenza ngokuFanelekileyo kunye neendleko

Isigqibo phakathi kwe-single-cavity kunye ne-multi-cavity molds ichaphazela kakhulu ukusebenza kakuhle kunye nokuphumelela kweendleko zenkqubo ye-thermoforming. Ukubumba okunomqolo omnye, ukuvelisa into enye ngexesha, kunika ubulula kunye nokulula ukulawula kodwa kunokurhoxa kwisantya esipheleleyo semveliso. Kwelinye icala, ukubumba okunemingxuma emininzi kwenza ukwakheka kwangaxeshanye kweemveliso ezininzi, ukomeleza amaxabiso emveliso kodwa kufunwa ukusetwa okuntsonkothileyo. Eli candelwana liqhuba uhlalutyo oluneenkcukacha lwemveliso esebenzayo kunye neendleko ezinxulumene nazo zombini iintlobo zokungunda, lixhobisa abavelisi ukuba benze ukhetho olucwangcisiweyo oluhambelana nesikali sabo semveliso kunye neemfuno.

Ukukhetha uhlobo olufanelekileyo lokungunda

Ukukhetha phakathi kwe-single-cavity kunye ne-multi-cavity molds kufuna ukuqonda okuncinci kweemfuno zemveliso. Imiba efana nomthamo woodolo, isantya semveliso esifunekayo, kunye nezixhobo ezikhoyo zidlala indima ebalulekileyo kule nkqubo yokwenziwa kwezigqibo. Ngokubonelela ngengqiqo kwiingqwalasela ezibandakanyekayo, eli candelo linceda abavelisi ekukhetheni uhlobo lokubumba olulungele iinjongo zabo zokusebenza kunye nemiqobo yezoqoqosho.

IV. Iingqwalasela eziphambili ekuKhethweni kokungunda

Ukukhethwa kwezinto eziphathekayo kunye noKuhlala ixesha elide

Ukukhetha izinto ezifanelekileyo zokubumba kubaluleke kakhulu ekuqinisekiseni ixesha elide kunye nokusebenza kwazo. Kulo mongo, ukusetyenziswa kwe-6061 i-alloy plate ye-aluminium ivelele kwiimpawu zayo eziphawulekayo. Amandla endalo kunye nokumelana nokunxiba kwale ngxubevange kunegalelo ekomeleleni kokubumba, okubavumela ukuba bamelane neemeko ezinzima zeenkqubo ze-thermoforming. Ukongeza, ukuxhathisa ukubola kwe-aluminium yealloyi kwandisa ngakumbi ukomelela okupheleleyo kokubumba, kubenze bafanelekele ukusetyenziswa ixesha elide kunye nobunzima.

IiMfuno zoyilo kunye nokuChaneka

Uyilo lokungunda ludlala indima ebalulekileyo ekufezekiseni ukuchaneka okufunekayo kwi-thermoforming. Xa ukhetha iipleyiti ze-6061 ze-alloy aluminium, ubuchule babo obukhethekileyo buququzelela ukudalwa koyilo oluntsonkothileyo lokungunda ngokuchaneka okuphezulu. Ukukwazi ukufezekisa ukunyamezela okuqinileyo kunye neenkcukacha eziyinkimbinkimbi ziqinisekisa ukuba i-molds ihlangabezana neenkcukacha ezichanekileyo ezifunekayo ekuveliseni iimveliso zeplastiki eziphezulu. Eli candelwana liphonononga ubudlelwane be-symbiotic phakathi koyilo lokungunda kunye nokuchaneka, ligxininisa indlela i-6061 ye-alloy aluminium ixhasa ngayo ukufezekiswa kobumbeko olunzima kunye noluchanekileyo lokubumba.

Iindleko kunye nokuSebenza ngokuSebenzayo kweMveliso

Ukulinganisa iindleko kunye nempumelelo yemveliso yingqwalasela ebalulekileyo ekukhetheni ukungunda. Ngelixa i-6061 i-alloy aluminium plates inokubandakanya utyalo-mali lokuqala, ukuphumelela kweendleko zabo kwixesha elide kufuneka kuthathelwe ingqalelo. Ubume obulula be-aluminiyam bunciphisa ubunzima obupheleleyo be-molds, enokuthi iholele ekugcinweni kwamandla kunye nokuphucula ukusebenza kakuhle. Ngaphezu koko, ukukhululeka komatshini we-aluminium kunegalelo kwiinkqubo zokuvelisa ngokukhawuleza, ezichaphazela indleko-ngempumelelo. Eli candelo lihlukanisa ukurhweba phakathi kweendleko kunye nokusebenza kakuhle kwemveliso, enika ingqiqo malunga nendlela ukukhethwa kwezinto zokubumba, ngokukodwa i-aluminium ye-6061 ye-alloy, inokuchaphazela imiba yezoqoqosho kwimisebenzi ye-thermoforming.

V. Iinkqubo kunye nokwabelana ngamava

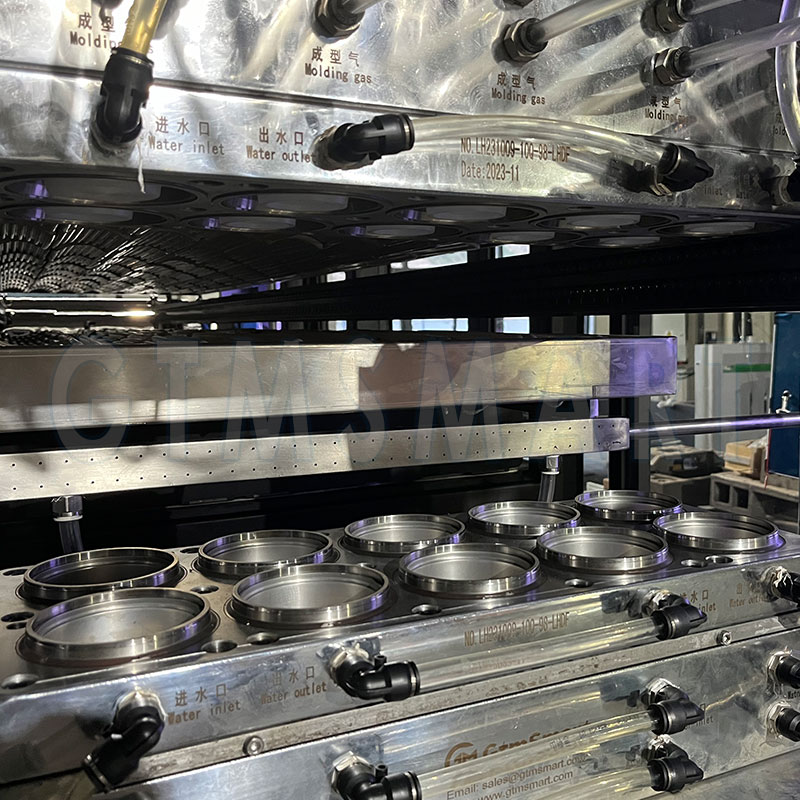

Kwindawo ye-thermoforming, i-GtmSmartUmatshini wokwenza indebe olahliweyo imi njengophononongo oluqaphelekayo, ngakumbi ekukhetheni kwayo imathiriyeli yokungunda. Imibumbo esetyenziswayo ikakhulu isebenzisa iipleyiti zealluminiyam eziyi-6061. Olu khetho lwangabom luqhutywa ngumnqweno wokusebenzisa iingenelo ezahlukileyo ezibonelelwa yile ngxubevange ye-aluminium kwindawo yokuvelisa ikomityi elahlayo.

Uhlalutyo lweempawu eziphawulekayo

Ukusetyenziswa kweepleyiti ze-aluminium ze-6061 kwi-alloyikomityi yeplastiki thermoforming machinei-mold iveza izinto ezininzi eziphawulekayo:

1. Ukuqina kunye Nobude Obude: Amandla endalo ye-6061 ye-alloy aluminium iqinisekisa ukuqina kwe-molds, ebavumela ukuba baxhathise ukufudumeza okuphindaphindiweyo kunye nokwenza imijikelezo ehambelana nokuveliswa kwevolumu ephezulu yeekomityi ezilahlayo. Ukumelana nokunxiba kunye nokukrazula kunegalelo kubomi obude bokungunda kunye nomgangatho wemveliso ongaguqukiyo.

2. Ukuchaneka kuLwakhiwo lweNdebe: I-machinability ekhethekileyo ye-6061 i-alloy aluminium iququzelela ukudalwa kwe-molds kunye noyilo oluyinkimbinkimbi kunye neenkcukacha ezichanekileyo. Oku kuchanekileyo kubaluleke kakhulu ekufezekiseni ukufana kwiindebe ezibunjiweyo, ukuhlangabezana nemigangatho ephezulu elindelekileyo kushishino lwekomityi elahlayo.

3. IMveliso eNgenexabiso: Ngelixa utyalo-mali lokuqala kwi-6061 i-alloy aluminium plates ingaba phezulu, i-long-term-effectiveness-effectiveness ibonakala. Ubume obulula be-aluminiyam bunciphisa ubunzima obupheleleyo be-molds, enokuthi iholele ekugcinweni kwamandla kunye nokuphucula ukusebenza kakuhle. Ukukhululeka komatshini we-aluminium kwakhona kunegalelo kwiinkqubo zemveliso ezikhawulezayo, ukwandisa iindleko-ukusebenza kwe-Smart Disposable Cup Forming Machine.

Olu pho nonongo lubonisa indlela ukhetho olucwangcisiweyo lwezinto zokubumba, ezifana ne-6061 i-aluminium alloy, inokuchaphazela kakhulu ukusebenza, ukuqina, kunye neendleko-zokusebenza kweenkqubo ze-thermoforming kwizicelo zehlabathi zangempela.

Ukuqukumbela

Ukuqukumbela, uphononongo olubanzi lwetekhnoloji ye-thermoforming, iintlobo zokubumba, kunye nokuqwalaselwa okuphambili ekukhetheni ukubumba kugxininisa ukuhlangana okuntsonkothileyo kwezinto ezibumba imbonakalo yomhlaba wokwenziwa kweplastiki. Ukusetyenziswa kweepleyiti ze-6061 zealluminiyam njengesixhobo sokubumba esibalaseleyo kuvela njengokhetho olunengqiqo, lunikeza ibhalansi ebuthathaka phakathi kokuqina, ukuchaneka, kunye nokusebenza kakuhle kweendleko. Uphononongo lwemeko yeGtmSmartumatshini wokwenza ikomityi yeplastikingumzekelo weziphumo eziphathekayo zolu khetho lwezinto eziphathekayo, ubonisa indlela enegalelo ngayo ekusebenzeni komatshini, ixesha elide, kunye nokuveliswa kweekomityi ezilahlwayo eziphezulu.

Ixesha lokuposa: Dec-18-2023