Sisebenza njani isitishi sokupakisha kuMatshini weThermoforming

I. Intshayelelo

Kwindawo yokuvelisa,oomatshini be-thermoforming idlala indima ebalulekileyo ekubumbeni imathiriyeli ekrwada ibe yimveliso echanekileyo. Phakathi kwamacandelo ahlukeneyo aba matshini, isikhululo sokupakisha ngokuthula siqhuba umsebenzi obalulekileyo, ukulawula amanyathelo okugqibela enkqubo ye-thermoforming. Eli nqaku lijolise ekuboneleleni ngeenkcukacha zezikhululo zokupakisha. Ukukhonza njengecandelo elibalulekileyo kumgca wokuvelisa i-thermoforming, izikhululo zokupakisha zinegalelo ekusebenzeni kakuhle, ukunciphisa abasebenzi, kunye nokuqinisekiswa kweemveliso ezikumgangatho ophezulu. Sijoyine njengoko sivavanya ukusebenza kwangaphakathi kwezitishi zokupakisha, sivavanya amacandelo azo, iindlela, izinto eziluncedo, kunye nefuthe elibambekayo elizizisayo kwitekhnoloji ye-thermoforming.

II. Ukuqonda oomatshini bePlastiki beThermoforming

Inkqubo ye-thermoforming yindlela yokuvelisa esetyenziswa ngokubanzi yokubumba amaphepha eplastiki kwiimveliso ezahlukeneyo. Le nkqubo ibandakanya amanyathelo aphambili aliqela, ukuqala ngokufudumeza ishidi leplastiki lide libe linokuphepheka. Emva koko, ishidi elithambileyo libunjwa kwimilo ethile usebenzisa i-mold okanye uchungechunge lokubumba. Emva kokuba ifom efunwayo ifunyenwe, imveliso yeplastiki ipholisa kwaye iqiniswe ukugcina imilo yayo. Ukuqonda le nkqubo ingundoqo kunika isiseko sokuqonda ukubaluleka kwamacandelo athile ngaphakathiumatshini we-thermoforming ozenzekelayo ngokupheleleyo . Oku kulandelayo ngamacandelo omatshini we-thermoforming:

| Isitishi | Intsingiselo |

| Ukwenza isitishi | Isikhululo sokubumba sisigaba esibalulekileyo apho iphepha leplastiki elifudunyeziweyo liguqulwa libe yimilo yemveliso ejoliswe kuyo. |

| Isikhululo sokusika | Ukulandela isiteji sokwenza, iphepha leplastiki kunye neemveliso ezibunjiweyo zihambela kwisikhululo sokusika. |

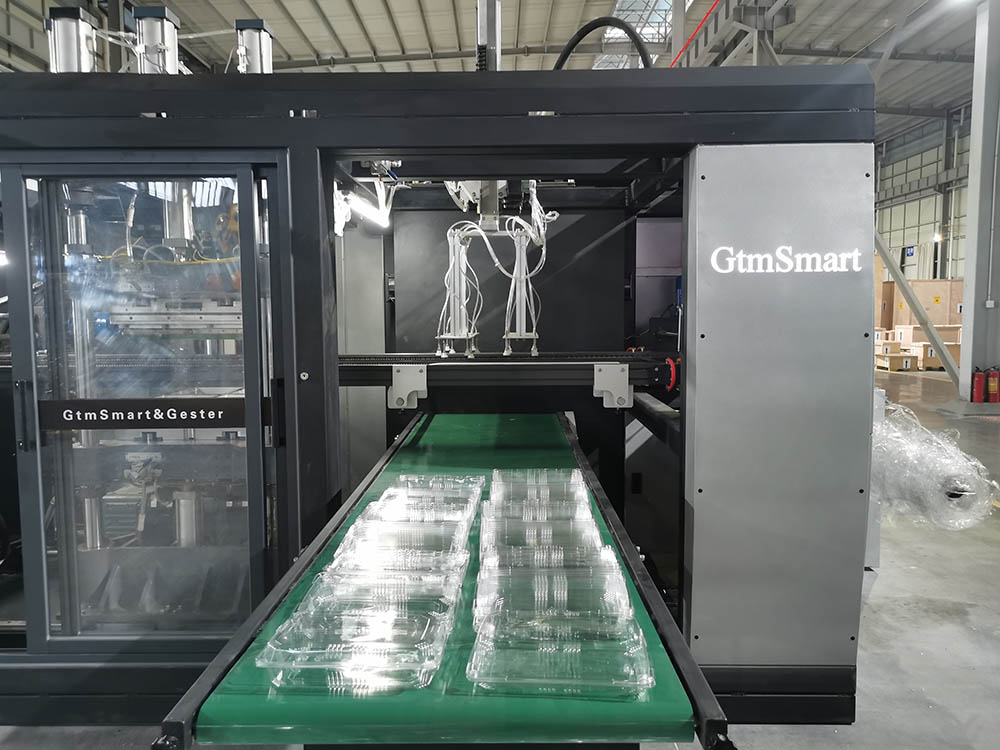

| Isitishi sokupakisha | Isikhululo sokupakisha esisebenza njengenqanaba lokuqukumbela kwinkqubo ye-thermoforming. |

Ukufumana ulwazi kula macandelo ahlukeneyo kubonelela ngokucokisekileyo malunga nendlela umatshini we-thermoforming osebenza ngayo. Esi sikhululo sokupakisha sithatha uxanduva lokulungelelanisa ngokufanelekileyo kunye nokuqokelela iimveliso zeplastiki ezibunjiweyo, zilungiselele amanyathelo alandelayo okupakisha kunye nokusabalalisa.

III. Isitishi sokupakisha: Iziseko

Isikhululo sokupakisha ngaphakathi kumatshini we-thermoforming yinxalenye esisiseko eyenzelwe ukulawula ngokufanelekileyo utshintsho ukusuka kwisigaba sokubumba kunye nokusika ukuya kwisigaba sokugqibela sokupakisha. Injongo yayo ephambili kukuqokelela ngokucwangcisiweyo kunye nokulungelelanisa iimveliso zeplastiki ezenziweyo, ukuqinisekisa ukuhamba komsebenzi kunye nokuququzelela iinkqubo ezilandelayo. Ibekwe ezantsi ukusuka kwisikhululo sokusika, isebenza njengomlamli phakathi kokuveliswa kweemveliso zeplastiki kunye nokulungiswa kwazo ukupakishwa.

Imisebenzi ephambili yesiKhululo sokupakisha:

1 . Ukuqokelelwa kweeMveliso eziSekiweyo:

Omnye wemisebenzi ephambili yesikhululo sokupakisha kukuqokelelwa okucwangcisiweyo kweemveliso zeplastiki ezisanda kwenziwa. Njengoko ezi mveliso zivela kwisikhululo sokusika, isikhululo sokupakisha siqokelela ngokufanelekileyo, sithintela naluphi na ukuphazamiseka kumgca wokuvelisa. Eli nyathelo lokuqala libalulekile ekugcineni inkqubo yokuvelisa eqhubekayo nelungelelanisiweyo.

2. Ukupakishwa kokuPhathwa ngokuLula kunye nokuPakisha:

Emva kokuba iqokelelwe, isikhululo sokupakisha sihamba phambili ngokucwangcisa iimveliso ezenziwe ngendlela ehleliweyo. Oku kupakishwa akuncedi nje ukuphatha lula kodwa kukwakhulisa isigaba sokupakisha. Ulungelelwaniso olucwangcisiweyo luqinisekisa ukuba iimveliso zibonakaliswe ngokufanayo, zilungelelanisa amanyathelo alandelayo okupakishwa kunye nokusabalalisa. Lo msebenzi uphucula ukusebenza kakuhle kunye nokunciphisa umngcipheko womonakalo ngexesha lokuphatha kunye nokuthutha.

IV. Izinto eziluncedo zokuSebenzisa isitishi sokupakisha

Ukubandakanya izikhululo zokupakisha kwiumatshini weplastiki we-thermoforming izisa intaphane yeenzuzo, ukusuka ekuphuculweni kobuchule kunye neemfuneko ezincitshisiweyo zabasebenzi ukuya kwimpatho ephuculweyo yemveliso kunye nokupakishwa, kunye nemilinganiselo yokulawula umgangatho owomeleziweyo. Ezi nzuzo ngokudibeneyo zinegalelo kwinkqubo yokuvelisa eyomeleleyo nekhuphisanayo kwindawo yemveliso yeplastiki.

1. Ukwandiswa kokuSebenza kwiMveliso:

Izikhululo zokupakisha zinegalelo elibonakalayo ekunyuseni impumelelo kumgca wemveliso weoomatshini be-thermoforming . Ngokuzenzekelayo ukuqokelela kunye nokulungelelaniswa kweemveliso zeplastiki ezenziweyo, ezi zikhululo zisusa imiqobo enokuthi yenzeke ukuba le nkqubo ibiyincwadana. Ukupakishwa okuqhubekayo kunye nokucwangcisiweyo kweemveliso kuqinisekisa ukuhamba komsebenzi, ukunciphisa ixesha elingasebenziyo phakathi kwezigaba ze-thermoforming. Ngenxa yoko, abavelisi babona ukonyuka okubonakalayo ekusebenzeni kakuhle kwemveliso.

2. UkuNcitshiswa kweeMfuno zeMisebenzi:

Olunye uncedo olubalaseleyo lokubandakanya izikhululo zokupakisha kukwehla okuqaphelekayo kwiimfuno zabasebenzi. Ukuzenzela ngokuzenzekelayo ukuqokelela kunye neenkqubo zokupakisha kunciphisa imfuno yokungenelela ngesandla kule misebenzi ephindaphindiweyo kunye nexesha. Oku akunciphisi iindleko zabasebenzi kuphela kodwa kukwavumela abasebenzi abanezakhono ukuba bagxile kwimiba entsonkothileyo yenkqubo yokwenziwa kwemveliso, ngaloo ndlela kunyuswa ukwabiwa kwezibonelelo zabasebenzi kwiziko lemveliso.

3. UkuPhathwa kweMveliso ePhuculweyo kunye nokuPakisha:

Izitishi zokupakisha zidlala indima ebaluleke kakhulu ekwandiseni ukuphathwa kunye nokupakishwa kweemveliso ze-thermoformed. Ukupakishwa okucwangcisiweyo kweemveliso kuqinisekisa umboniso ofanayo, okwenza kube lula kwiinkqubo ezisezantsi ezifana nokupakishwa kunye nokusabalalisa. Olu phuculo ekuphatheni alugcini nje ukulungelelanisa izigaba ezilandelayo kodwa lunegalelo ekunciphiseni umngcipheko womonakalo ngexesha lokuthutha. Uphuculo lulonke ekuphathweni kwemveliso yongeza umaleko wobuchule kwimiba yolungiselelo kunye nokuhanjiswa kwekhonkco lemveliso.

4. Ulawulo loMgangatho olongezelelweyo:

Izitishi zokupakisha zisebenza njengendawo yokukhangela ebalulekileyo yolawulo lomgangatho ngaphakathi kwenkqubo ye-thermoforming. Ngokupakishwa ngokuzenzekela, ezi zikhululo zinokubandakanya iindlela zokuhlola ukuchonga nokwahlula naziphi na iimveliso ezineziphene. Oku kwandisa imilinganiselo yolawulo lomgangatho jikelele ngokuthintela izinto ezingekho mgangathweni ukuba ziqhubele phambili ezantsi kumgca wemveliso. Ngenxa yoko, abavelisi banokugcina umgangatho wemveliso ongaguqukiyo kwaye bahlangabezane nemigangatho engqongqo efunwa yimarike.

V. Isiphelo

Ukuqukumbela, izikhululo zokupakisha zimi njengamacandelo abalulekileyo ngaphakathi kwenkqubo ye-thermoforming, indima yazo ebalulekileyo ekuqokeleleni, ukulungelelanisa, kunye nokujonga umgangatho-ukukhangela izinto ezenziweyo zigxininisa ukubaluleka kwazo ekuqinisekiseni umgca wemveliso osebenzayo kunye nocwangcisiweyo. Izibonelelo eziphambili zezikhululo zokupakisha, kubandakanywa ukunyuka kwemveliso, ukunciphisa iimfuno zabasebenzi, ukuphathwa kwemveliso ephuculweyo, kunye nokulawulwa komgangatho ophuculweyo, kugxininise impembelelo yabo yenguqu kwindalo yokwenziwa kweplastiki. Ukujonga phambili, ikamva letekhnoloji yokupakisha itekhnoloji ibambe iindlela ezithembisayo, kunye nenkqubela phambili eqhubekayo kwi-automation, itekhnoloji ehlakaniphile, kunye neendlela zokuhlola umgangatho.

Ixesha lokuposa: Dec-14-2023