Uyilwa njani i-Thermoforming Molds Multi-Cavity Molds?

Uyilwa njani i-Thermoforming Molds Multi-Cavity Molds?

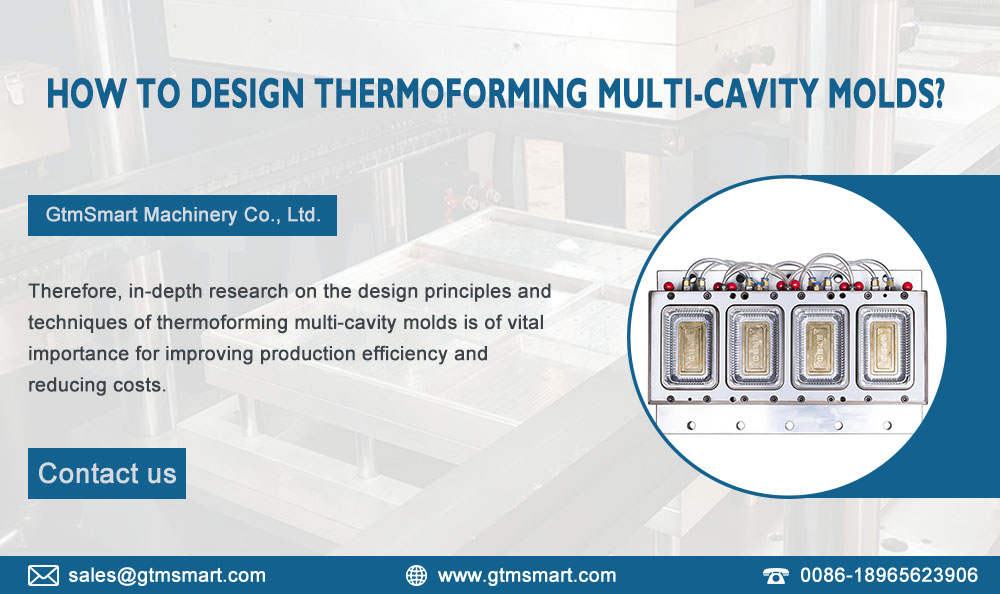

Ngokwandiswa okuqhubekayo kwemarike yeemveliso zeplastiki yehlabathi kunye nokwenziwa kwezinto ezintsha zobugcisa, uyilo lweumatshini we-thermoforming iimold multi-cavity ziye zaba sisihloko senkxalabo enkulu kushishino lweemveliso zeplastiki. Kwiinkqubo zokubumba iplastiki, uyilo lokubumba luchaphazela ngokuthe ngqo ukusebenza kakuhle kwemveliso, umgangatho wemveliso, kunye nolawulo lweendleko. Ke ngoko, uphando olunzulu malunga nemigaqo yoyilo kunye nobuchule be-thermoforming i-multi-cavity molds ibaluleke kakhulu ekuphuculeni ukusebenza kakuhle kwemveliso kunye nokunciphisa iindleko.

1. Imigaqo-siseko ye-Thermoforming ye-Multi-Cavity Molds

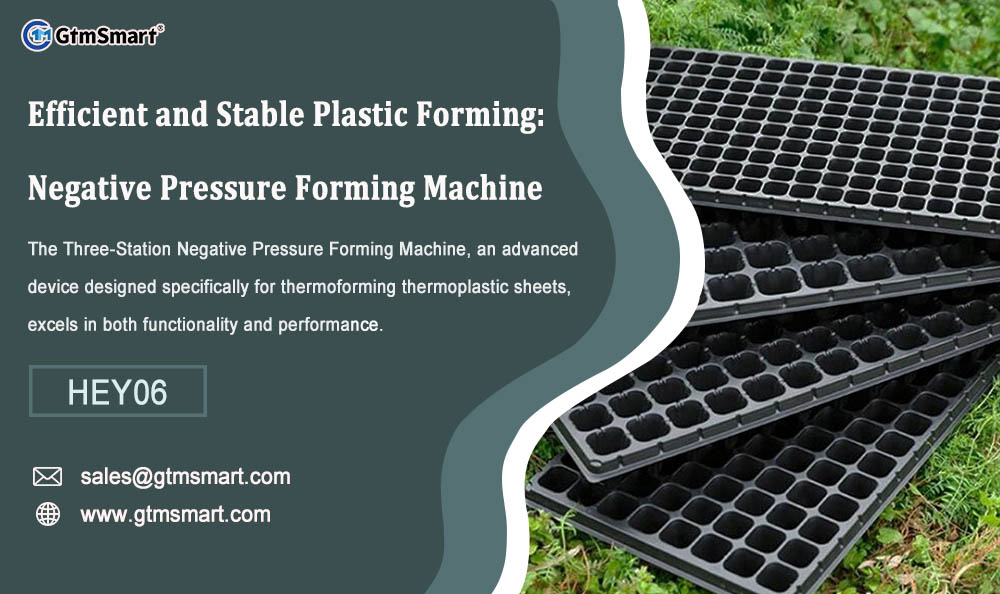

I-Thermoforming multi-cavity molds zingundo ezisebenzisa inkqubo yokufudumeza ukufudumeza imathiriyeli ekrwada yeplastiki ukuya kwimeko etyhidiweyo, kwaye emva koko ifake iplastiki etyhidiweyo kwimingxuma yokubumba ukuze ibunjwe ngenkqubo yembaleki. Xa kuthelekiswa nokubunjwa kwe-cavity yendabuko, i-multi-cavity molds inokubumba iimveliso ezininzi ngaxeshanye, kunye nokusebenza okuphezulu kwemveliso kunye neendleko eziphantsi.

2. Uyilo olubalulekileyo kunye neNgqwalasela yoBugcisa

Ukukhethwa kwezinto eziphathekayo kunye nokuchasana nokushisa: Ukukhethwa kwezinto zokubumba enye yezinto ezibalulekileyo ezichaphazela ukusebenza kwesikhunta. Izinto zokubumba ezisetyenziswa ngokuqhelekileyo ziquka intsimbi yesixhobo, insimbi engenasici, njl., kwaye kuyimfuneko ukukhetha ngokufanelekileyo izinto ezisekelwe kubushushu obuthile bokubumba kunye neempawu zeplastiki zeplastiki ukuqinisekisa ukuba ukubumba kunokumelana nokushisa okulungileyo kunye neempawu zoomatshini.

2.1 Uyilo lweMbaleki: Uyilo lombaleki luchaphazela ngokuthe ngqo ukuhamba kweplastiki kwi-mold, echaphazela umgangatho wokubumba imveliso kunye nokusebenza kakuhle kwemveliso. Uyilo oluchanekileyo lwesakhiwo somgijimi siqinisekisa ukuhamba okufanayo kweplastiki, ukuphepha iziphene ezifana namaqamza omoya kunye nemigca enyibilikayo.

2.2 Inkqubo yokupholisa: Uyilo lwenkqubo yokupholisa luchaphazela isantya sokupholisa kunye nokufana kokubumba, okuchaphazela ngokuthe ngqo umjikelezo wemveliso kunye nomgangatho wemveliso. Ngoyilo olufanelekileyo lwenkqubo yokupholisa, ukusebenza kakuhle kokupholisa ngundo kunokuphuculwa, imijikelo yokubumba ibe mfutshane, kwaye iindleko zemveliso zincitshisiwe.

2.3 Uyilo lweCavity:Uyilo lwe-Cavity kufuneka luyilwe ngokufanelekileyo ngokweempawu zesakhiwo semveliso kunye neemfuno zenkqubo yokubumba ukuqinisekisa ukuba isikhunta sinokuphindaphinda ngokuchanekileyo imilo kunye nobukhulu bemveliso ngelixa unciphisa uxinzelelo kunye nokuguqulwa ngexesha lokubunjwa kwemveliso.

2.4 Inkqubo yokulawula ubushushu:Ukuzinza kwenkqubo yokulawula ubushushu kubalulekileumatshini weplastiki we-thermoforming iinkqubo. Ngeenkqubo ezichanekileyo zokulawula ubushushu, ukuzinza kweqondo lokushisa kunokuqinisekiswa, ukuphepha imiba esemgangathweni ebangelwa ukuguquguquka kweqondo lokushisa.

2.5 Indlela yokubumba:Uyilo lwendlela yokubumba kufuneka luqwalasele iimpawu zesakhiwo sokubumba kunye neemfuno zenkqubo yokubumba ukuze kuqinisekiswe ukuba isikhunta sinokuvula nokuvala ngokuchanekileyo nangokuzinzileyo, ukuphepha iziphene zemveliso ezibangelwa ukuvulwa nokuvala i-mold embi.

3. Izinto eziluncedo kunye nemingeni ye-Thermoforming Multi-Cavity Molds

I-Thermoforming i-multi-cavity molds ineenzuzo ezininzi ngaphezu kwe-mold ye-cavity yendabuko, efana nokusebenza okuphezulu kwemveliso, ixabiso eliphantsi, kunye nomgangatho wemveliso ozinzile. Nangona kunjalo, ukuyila kwabo kunye neenkqubo zokuvelisa nazo zijongene nemingeni, efana noyilo lwembaleki enzima kunye nobunzima bokulawula inkqubo yokupholisa. Ke ngoko, abasebenzi boyilo kufuneka babe nemigangatho ephezulu yobuchwephesha kunye namava atyebileyo ukuyila umgangatho ophezulu kunye nokusebenza kakuhle kwe-thermoforming molds multi-cavity.

4. Ukusetyenziswa kweTekhnoloji ye-Thermoforming kwi-Mold Design

Kuyilo lwe-thermoforming molds multi-cavity, iteknoloji ye-thermoforming ngokuzenzekelayo idlala indima ebalulekileyo. Ngokulawula ubushushu bokubumba, iingxaki ze-shrinkage kunye ne-deformation yeplastiki ngexesha lokubumba zingasombululwa ngokufanelekileyo, ukuphucula ukuchaneka kwemveliso kunye nomgangatho ophezulu. Ukongeza, uyilo olunengqiqo lwembaleki eshushu inokufezekisa ukuzaliswa okufanayo kwezixhobo zeplastiki, ukunciphisa iziphene ezinje ngamaqamza omoya kunye nokudubula okufutshane, kunye nokuphucula inkangeleko yemveliso kunye nokusebenza.

5. UYilo kunye nokuPhuculwa kweMulti-Cavities

Uyilo kunye nokulungiswa kwe-multi-cavities yimiba ephambili kwi-design of thermoforming multi-cavity molds. Kuyilo loyilo, izinto ezinje ngesakhiwo semveliso, ubungakanani, kunye nenkqubo yokubumba kufuneka ziqwalaselwe ukumisela inani kunye nendawo yecavities ukufezekisa ezona ziphumo zokubumba. Kuyilo lokuphucula, ukusebenza komngundo kunye nokuzinza kunokuphuculwa ngakumbi ngokulungisa isakhiwo sembaleki, ukwandisa iinkqubo zokupholisa, kunye nokuphucula iinkqubo zokukhupha umoya.

6. Ukukhethwa kwezinto eziphathekayo kunye neTekhnoloji yoLungiso

Kuyilo lwe-thermoforming i-multi-cavity molds, ukhetho lwezinto eziphathekayo kunye neteknoloji yokucubungula kubaluleke ngokulinganayo. Izinto zokubumba kufuneka zibe nokumelana nokushisa okulungileyo, ukuqina, kunye nokumelana nokunxiba ukuqinisekisa ukusebenza okuzinzileyo kwexesha elide. Kwangaxeshanye, itekhnoloji yokucubungula efanelekileyo efana ne-CNC machining, i-EDM, njl., kufuneka ikhethwe ngokweemfuno zemveliso kunye nomlinganiselo wokuvelisa ukuqinisekisa ukuchaneka kwesikhunta kunye nokuthembeka.

7. ULondolozo lokungunda kunye noLawulo

Okokugqibela, ukugcinwa nokulawulwa kweumatshini wokwenza uxinzelelo ii-multi-cavity molds zingundoqo ekuqinisekiseni ukusebenza kwazo okuzinzile kwexesha elide. Ukuhlolwa rhoqo kweengubo kunye nokulimala kwesikhunta, ukulungiswa kwangexesha kunye nokutshintshwa, kuyimfuneko ukuqinisekisa ukunyaniseka kunye nokusebenza okuzinzile kwesikhunta. Okwangoku, ukuseka inkqubo yokulawula i-mold yesayensi, ukuqinisa uqeqesho malunga nokusetyenziswa kwe-mold kunye nokugcinwa, kunokuphucula ukusetyenziswa kwe-mold kunye nobomi benkonzo.

Ukuqukumbela, uyilo lokubumba i-thermoforming multi-cavity molds lubandakanya iinkalo ezininzi, ezifuna ukuqwalaselwa ngokubanzi kwezinto eziphathekayo, iinkqubo, ukwakheka, njl., Ukufezekisa iziphumo ezingcono zokubumba kunye neenzuzo zoqoqosho. Kuphela ngokuphonononga okuqhubekayo kunye nokutsha, ukuphuculwa okuqhubekayo koyilo kunye namanqanaba obugcisa, umntu unokuma engoyiswanga kukhuphiswano oluqatha lwemarike.

Umatshini weThermoforming wezikhululo ezininzi

Umatshini weThermoforming wezikhululo ezininzi Isitishi esinye seThermoforming Machine

Isitishi esinye seThermoforming Machine