ULinyuswa njani ngokuSebenzayo kweMveliso ngoomatshini bokwenza uxinzelelo olubi

Intshayelelo

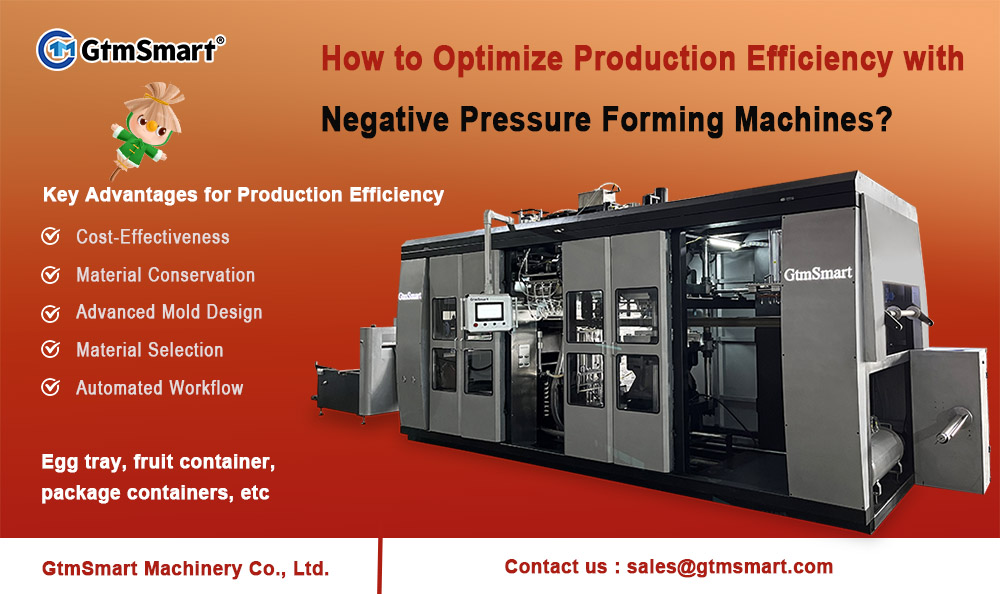

Kwimeko yanamhlanje ekhawulezayo yokwenziwa kwemveliso, ukwandisa ukusebenza kakuhle kwemveliso yeyona nto iphambili kumashishini afuna ukuhlala ekhuphisana. Itekhnoloji enye ethe yafumana ingqwalasela ebalulekileyo kolusukelo nguMatshini wokwenza uxinzelelo olubi. Ngobuchule bawo obukhethekileyo, lo matshini ubonelela ngobuninzi beenzuzo zokuphucula ukusebenza kakuhle kwemveliso kuwo wonke amashishini ahlukeneyo. Kweli nqaku, siza kuphonononga kubuchwephesha boomatshini boMoya woxinzelelo lwe-Thermoforming kwaye siphonononge izicwangciso zokwandisa amandla abo ekusebenzeni kakuhle.

Ukuqonda Ukwenziwa Koxinzelelo Olubi

Oomatshini bokwenza uxinzelelo olubi , zizixhobo eziguquguqukayo ezisetyenziselwa ukubumba kunye nokubumba uluhlu olubanzi lwemathiriyeli, uninzi lweplastiki. Inkqubo ibandakanya ukusebenzisa uxinzelelo lwe-vacuum ukuzoba amashidi e-thermoplastic ashushu kwi-molds, ukudala iimilo eziyinkimbinkimbi kunye nezakhiwo ngokuchanekileyo. Le ndlela igqamile ngenxa yokuguquguquka kwayo, ukusebenza kakuhle kweendleko, kunye nesantya, oko kuyenza ibe lolona khetho lufanelekileyo kuzo zombini iiprototyping kunye nemveliso enkulu.

Izinto eziluncedo ezingundoqo kwiMveliso eFanelekileyo

1. Iindleko-Ngempumelelo kunye noLondolozo lweMathiriyeli

I-Negative Pressure Forming inokunciphisa kakhulu inkcitho yezinto eziphathekayo xa kuthelekiswa neendlela zokuvelisa ezithathayo. Ubume obuchanekileyo benkqubo bunciphisa imathiriyeli engaphezulu, ibe negalelo ekongiweni kweendleko kunye nezenzo ezihambelana nokusingqongileyo. Ukongeza, iindleko ezisezantsi zezixhobo ezinxulumene nale ndlela ziyenza ibe lukhetho olunomtsalane kwimiba emincinci ukuya kwephakathi kwemveliso.

2. Advanced Mold Design

Utyalo-mali kwimibumbo eyilwe kakuhle sisicwangciso esibalulekileyo sokuphucula ukusebenza kakuhle kwemveliso ngoomatshini bokwenza uxinzelelo olubi. Iimbumba ezilungiselelwe ijometri ethile yemveliso zinciphisa imiba yokusabalalisa izinto kwaye ziqinisekise ukufana kwimveliso yokugqibela. Ukusebenzisa isoftware yoyilo oluncediswa yikhompyuter (CAD) kunye nobuchule bokwenza okongeziweyo kunokunceda ukwenza imibumbo entsonkothileyo ephucula inkqubo iyonke.

3. Ukukhethwa kwezinto

Ukukhetha imathiriyeli efanelekileyo ye-thermoplastic kubalulekile ekuphumezeni iziphumo ezilungileyo. Izinto ezifana nokuguquguquka kwezinto, ukumelana nobushushu, kunye nokulula kokubumba kudlala indima ebalulekileyo ekumiseleni ukusebenza kakuhle kwenkqubo. Ukusebenzisana neengcali zezinto eziphathekayo kunye nokuqhuba uvavanyo olucokisekileyo kunokunceda ekuchongeni ezona zinto zifanelekileyo kwiimfuno zakho zemveliso.

4. Ukuphunyezwa kokuhamba komsebenzi okuzenzekelayo

Ukudibanisa i-automation kwi-workflow kunokunyusa ukunyusa ukusebenza kwemveliso. Ukuzenzekela kunciphisa umngcipheko weempazamo zabantu, kwandisa ukungaguquguquki, kwaye kwenza umsebenzi oqhubekayo, ngaloo ndlela ukhuliseUxinzelelo kunye neVacuum ye-Thermoforming Machine ukusetyenziswa. Ukusuka ekulayisheni izinto eziluhlaza ukuya ekususeni iimveliso ezigqityiweyo, i-automation ihambisa yonke inkqubo, ukunciphisa ixesha lokuphumla kunye nokuphucula iziphumo.

Ukuqukumbela

Oomatshini bokwenza uxinzelelo olubi babonelela ngendlela enyanzelisayo yokuphucula ukusebenza kakuhle kwemveliso kuwo wonke amashishini ahlukeneyo. Ngokukwazi kwabo ukubonelela ngamaxesha akhawulezayo okutshintsha, iindlela zokonga imali, kunye nokhetho olunokwenziwa ngokwezifiso, aba matshini bakulungele ukuguqula iinkqubo zokwenziwa kwemveliso. Ngokwamkela uyilo lokungunda oluhambele phambili, ukukhetha izinto ngobuchule, kunye nokuhamba komsebenzi okuzenzekelayo, amashishini anokusebenzisa amandla apheleleyo oomatshini bokwenza uxinzelelo olubi kwaye bafumane umda wokukhuphisana kwihlabathi eliguqukayo lemveliso yanamhlanje.

Ixesha lokuposa: Aug-18-2023