Umatshini wokwenza iVacuum ngokuzenzekela ziindidi ezikhethekileyo zoomatshini bokwenza ivacuum abayilelwe ukwenza izikhongozeli zeplastiki eziqhelekileyo zokugcina ukutya kunye nokupakishwa. Aba matshini basebenzisa imigaqo esisiseko efanayo yokwenza ivacuum ukwenza izitya zodidi lokutya ezikhuselekileyo nezilungele ukuzisebenzisa.

Nalu ujongo oluthe kratya kwindlela osebenza ngayo umatshini wokwenza iVacuum ngokuzenzekela kunye nezinye zezicelo eziqhelekileyo zaba matshini:

1. Usebenza njani umatshini wokubumba i-Thermoplastic Vacuum?

Umatshini wokwenza i-Thermoplastic Vacuum usebenzisa indibaniselwano yobushushu, uxinzelelo, kunye nokufunxa ukwenza amaphepha eplastiki abe kwimilo oyifunayo. Inkqubo ibandakanya la manyathelo alandelayo:

- 1.1 Ukufudumeza iplastiki: Iphepha leplastiki lifudunyezwa lide libe lithambile kwaye lithambile. Ubushushu kunye nexesha lokufudumala liya kuxhomekeka kuhlobo kunye nobukhulu beplastiki esetyenziswayo.

- 1.2 Ukubeka iplastiki phezu komngundo: Iphepha leplastiki elifudunyeziweyo libekwa phezu komngundo okanye isixhobo esinemilo efunekayo yesingxobo. Umngundo uqhele ukwenziwa ngentsimbi okanye iplastiki kwaye unokwenziwa ngokwesiqhelo kwimveliso ethile.

- 1.3 Ukwenziwa kwevacuum: Umatshini wokwenza i-vacuum ye-Thermoplastic usebenzisa i-vacuum ukufunxa iplastiki eshushu kwi-mold. Uxinzelelo oluvela kwi-vacuum lunceda ukubumba iplastiki kwifom efunwayo.

- 1.4 Ukupholisa nokucheba: Yakuba yenziwe iplastiki, iyapholiswa ize ilungiswe ukuze kususwe nayiphi na imathiriyeli engaphezulu. Imveliso egqityiweyo isitya seplastiki esiqhelekileyo esingasetyenziselwa ukugcina ukutya okanye ukupakisha.

2. Izicelo eziqhelekileyo zeVacuum Forming Machineing Thermoforming

Umatshini wokwenza i-Thermoforming yeVacuum inezicelo ezininzi kushishino lokutya. Nazi ezinye zezona zinto zisetyenziswa kakhulu:

- 2.1 Ukupakishwa: Izikhongozeli ezenziwe ngevacuum zidla ngokusetyenziselwa ukupakishwa kokutya. Ezi zikhongozeli zinokulungiswa ukuze zilingane neemveliso ezithile kwaye zinokuyilwa zibe neempawu ezinjengezitywina ezibonisa ukonakala kunye neziciko ezikhawulezayo.

- 2.2 Ukugcinwa kokutya: Izikhongozeli ezenziwe ngevacuum zikwasetyenziselwa ukugcina ukutya. Ezi zikhongozeli zomelele kwaye azingeni moya, zinceda ukugcina ukutya kusitsha ixesha elide.

- 2.3 Ukulungiselela ukutya: Izikhongozeli ezenziwe ngofunxa zisetyenziselwa ukulungiselela ukutya kumakhitshi ashishinayo nakwiindawo zokutyela. Ezi zikhongozeli zinokulungiswa ukuze zilingane izahlulo ezithile kwaye zinokupakishwa kwaye zigcinwe lula.

- 2.4 Ukutya kunye nemisitho: Izikhongozeli ezenziwe nge-vacuum zikwasetyenziswa ekutyeni nakwimisitho. Ezi zikhongozeli zinokulungiswa zibe nophawu kunye neelogo kwaye zingasetyenziselwa ukuphakela okanye ukuthutha ukutya.

3. Ukukhetha i-Industrial Vacuum Forming Machine

Xa ukhetha iUmatshini wokwenza iVacuum yeShishini , izinto ezininzi ezifanele ziqwalaselwe, kuquka ubukhulu bomatshini, uhlobo lwempahla yeplastiki esetyenziswayo, nemveliso efunekayo. Kwakhona kubalulekile ukuqwalasela inqanaba lokuzenzekelayo kunye nokulungelelaniswa okufunekayo, kunye neendleko zomatshini kunye neemfuno zokugcinwa.

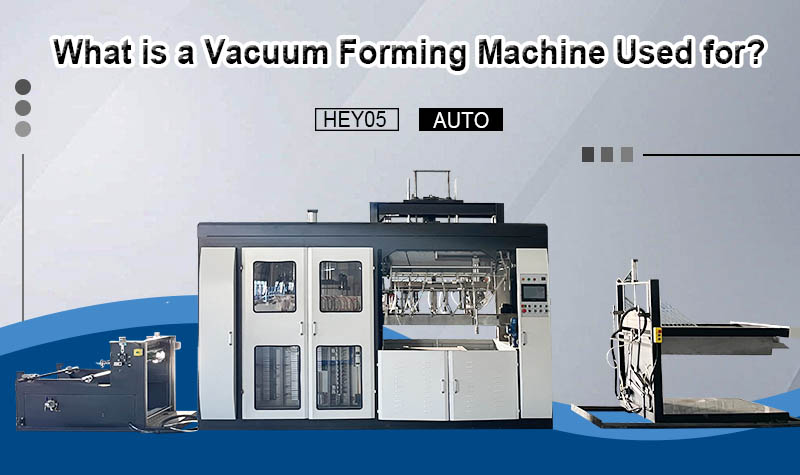

I-GtmSmart Umatshini wokwenza iPlastiki eVacuum eLungisiweyo

GtmSmartUmatshini wokwenza i-vacuum yePlastiki: Ikakhulu isetyenziselwa ukuveliswa kwezikhongozeli zeplastiki ezahlukeneyo (itreyi yeqanda, isikhongozeli seziqhamo, izikhongozeli zepakethe, njl.njl) ezinamashiti ashushu, anjengePET, PS, PVC njl.

- 3.1 Lo matshini wokwenza i-vacuum yePlastiki Usebenzisa inkqubo yokulawula i-PLC, i-servo iqhuba iipleyiti eziphezulu kunye nezantsi, kunye ne-servo feeding, eya kuzinza ngakumbi kwaye ichaneke.

- 3.2 I-Human-computer interface enenkcazo ephezulu yoqhagamshelwano-skrini, enokubeka iliso kwimeko yokusebenza kwayo yonke i-parameter setting.

- 3.3 Umatshini wokwenza i-vacuum yeplastiki Usebenzisa umsebenzi wokuzixilonga, onokubonisa ngexesha langempela ulwazi lokuphazamiseka, kulula ukuyisebenzisa kunye nokugcinwa.

- 3.4 Umatshini wokwenza i-vacuum ye-pvc unokugcina iiparitha ezininzi zeemveliso, kwaye ukulungiswa kweempazamo kukhawuleza xa kuvelisa iimveliso ezahlukeneyo.

4. Isiphelo

Ukuqukumbela, umatshini wokwenza i-Automatic Vacuum sisixhobo esikhethekileyo esisetyenziswa kwishishini lokutya ukwenza izikhongozeli zeplastiki zesiqhelo zokugcina ukutya kunye nokupakishwa. Ngokuqonda indlela abasebenza ngayo aba matshini kunye nezicelo ezahlukeneyo kunye neenzuzo, abavelisi bokutya kunye neenkampani zokupakisha banokukhetha umatshini wokwenza ivacuum efanelekileyo kwiimfuno zabo. Ngomatshini ofanelekileyo, banokwenza izikhongozeli zokutya ezikumgangatho ophezulu nezikhuselekileyo ezihlangabezana neemfuno zabathengi babo kunye nolindelo.

Ixesha lokuposa: Apr-13-2023