Ithini iMigaqo yokuSebenza yeTreyi ye-Egg yokuFaka i-vacuum Machine

Intshayelelo

Ukupakishwa kwamaqanda kuye kwahamba indlela ende ngokubhekiselele kwizinto ezintsha kunye nokuzinza. Enye yezona nkqubela zibalulekileyo kweli shishiniUmatshini wokwenza iTreyi yeqanda . Kweli nqaku, siza kuphonononga iinkcukacha ezintsonkothileyo zendlela lo matshini asebenza ngayo, esinika ukuqonda okubanzi kokusebenza kwawo.

Inkcazelo yokwenziwa kweVacuum

Ukwenziwa kwevacuum, ekwabizwa ngokuba yi-thermoforming, ukwenza uxinzelelo lwe-vacuum, okanye ukubumba i-vacuum, yinkqubo yokuvelisa esetyenziselwa ukubumba imathiriyeli yeplastiki kwiindlela ezahlukeneyo. Obu buchule buxhomekeke kwimigaqo yobushushu kunye ne-vacuum ukudala uyilo oluntsonkothileyo kunye nezakhiwo. Umatshini wokubumba weplastiki wokufunxa ubushushu ulandela le nkqubo ukuvelisa iitreyi zamaqanda ezisebenzayo nezilungele ukuphilisana kwendalo.

Izinto eziluncedo kwimveliso

-Inkqubo yokulawula ye-PLC: Intliziyo ye-Egg Tray Vacuum Forming Machine yinkqubo yayo yokulawula ye-PLC. Le teknoloji ephezulu iqinisekisa uzinzo kunye nokuchaneka kuyo yonke inkqubo yokuvelisa. Ngokusebenzisa i-servo drives kwiipleyiti zokungunda eziphezulu kunye nezantsi kunye nokutya kwe-servo, umatshini uqinisekisa iziphumo ezingaguqukiyo nezithembekileyo.

-Ujongano lweKhompyutha yomntu:Iiplastiki vacuum umatshini wokwenza thermal Ibonisa i-high-definition-screen touch-screen human-computer interface enikezela ngokujongwa kwexesha lokwenyani kuzo zonke izicwangciso zeparameter. Eli nqaku livumela abaqhubi ukuba bajonge umsebenzi wonke, beqinisekisa ukuba umatshini usebenza ngokufanelekileyo.

-Umsebenzi wokuZixilonga: Ukwenza umsebenzi kunye nokugcinwa kube lula ngakumbi, umatshini wokwenza i-vacuum yeplastiki uxhotyiswe ngomsebenzi wokuzixilonga. Eli nqaku libonelela ngolwazi lwexesha lokwenyani, okwenza kube lula kubasebenzisi ukujongana nayo nayiphi na imiba ngokukhawuleza nangempumelelo.

-Ugcino lweParameter yeMveliso:Iumatshini wokwenza ivacuum ezenzekelayo yenzelwe ukugcina iiparamitha zemveliso ezininzi. Lo mthamo wokugcina ulungelelanisa inkqubo yokuvelisa xa utshintsha phakathi kweemveliso ezahlukeneyo. Ukulungisa ingxaki kunye nohlengahlengiso lukhawuleza kwaye lungabinangxaki.

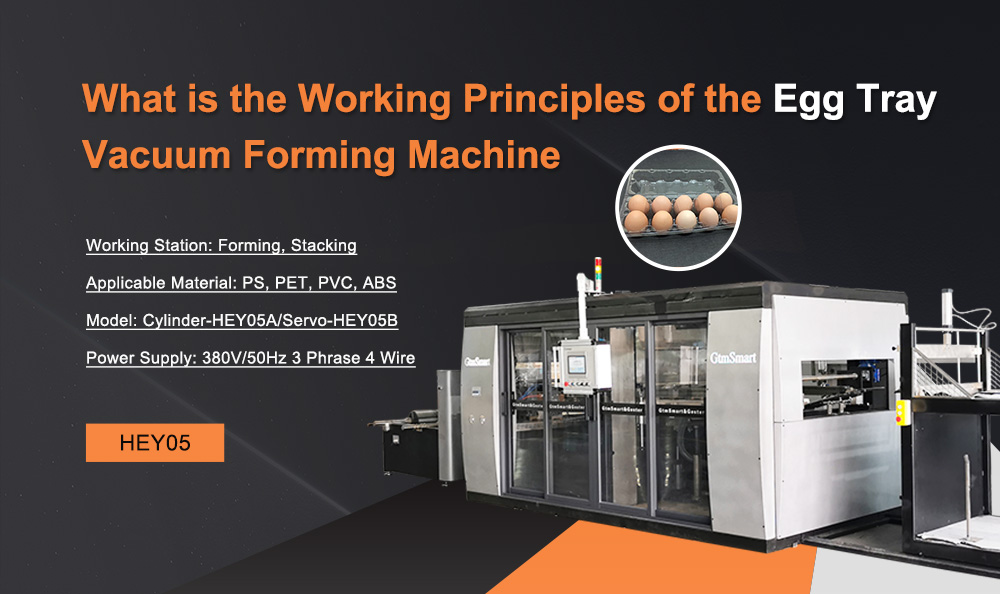

umatshini wokwenza i-vacuum yeqanda

Isitishi sokuSebenza: Ukuqulunqa kunye nokupakishwa

Isikhululo sokusebenza se-Egg Tray Vacuum Forming Machine sahlulwe ngokwezigaba ezibini ezibalulekileyo: ukwenza kunye nokupakisha. Makhe sihlolisise imigaqo yokusebenza yenqanaba ngalinye kula.

1. Ukubumba:

| Ukufudumeza: | Inkqubo iqala ngokufudumeza ishidi leplastiki ukuya kwiqondo lobushushu obulungileyo. Eli qondo lobushushu linokwahluka ngokuxhomekeke kuhlobo lweplastiki esetyenziswayo. |

| Ukubekwa kokungunda: | Iphepha leplastiki elifudunyeziweyo libekwe phakathi kokungunda okuphezulu nangaphantsi. Oku kubumba kuyilwe ngobuchule ukuhambelana nokumila kweetreyi zamaqanda. |

| Usetyenziso lweVacuum: | Nje ukuba iplastiki ibekwe endaweni, ivacuum ifakwa ngaphantsi, idala ukufunxa. Oku kutsala kutsalela iplastiki eshushu kwimingxuma yokungunda, yenze kakuhle imilo yetreyi yeqanda. |

| Ukupholisa: | Emva kwenkqubo yokubumba, iimbumba zipholile ukuze ziqiniswe iplastiki kwimo efunwayo. Eli nyathelo liyimfuneko ekugcineni imfezeko yesakhiwo. |

Ukwenza isitishi

2. Ukupakishwa:

| Ukukhutshwa kweTreyi yeqanda: | Nje ukuba iitreyi zamaqanda zithathe ukumila kwazo, zikhululwa ngononophelo kubungu. |

| Ukupakishwa: | Iitreyi zeqanda ezibunjiweyo ziye zipakishwe, ngokuqhelekileyo kwimiqolo, ukuzilungiselela ukuqhubeka okanye ukupakishwa. |

Isitishi sokupakisha

Ukuqukumbela

IUmatshini wokwenza iTreyi yeqanda kukusetyenziswa kwe-vacuum forming, edibene neempawu zayo eziphambili ezifana nenkqubo yokulawula ye-PLC, ujongano lwekhompyutha yomntu, umsebenzi wokuzixilonga, kunye nokugcinwa kweparameter, iqinisekisa iziphumo ezichanekileyo nezingaguqukiyo. Ukuqonda imigaqo yokusebenza yalo matshini kunika ukukhanya kwizinto ezintsha eziqhuba ishishini lokupakisha iqanda ekuzinzeni nasekusebenzeni kakuhle.

Ixesha lokuposa: Oct-19-2023